Content

In cleanroom management, approximately 80% of contaminants are introduced through the floor by personnel or handling equipment. As the first line of defense against contamination, sticky mats play a crucial role. However, with the wide variety of specifications available on the market, how do you choose the most suitable sticky mat for hospital operating rooms or high-standard cleanrooms?

1. Precise Matching of Viscosity

The core function of a sticky mat lies in its adhesive layer. Viscosity is usually categorized into three levels: high, medium, and low:

High viscosity: Suitable for semiconductor workshops and pharmaceutical operating rooms with extremely high cleanliness requirements. It can instantly capture tiny dust particles from shoe soles.

Medium/Low viscosity: Suitable for general industrial workshops or office entrances. Using a high-viscosity mat at a hospital ward entrance may cause difficulties for wheelchairs or trolleys, and even pose a tripping hazard for elderly people.

Recommendation: High viscosity should be chosen for cleanroom entrances, while a specially designed medium-viscosity model should be selected for areas with frequent wheeled transport (such as trolleys).

2. Material and Number of Layers

Currently, the mainstream product on the market is a 30-layer disposable sticky mat made of LDPE (low-density polyethylene).

Why 30 layers? This usually represents a month's supply (one layer removed daily). Each layer should have a numerical label to facilitate management and ensure the mat remains effective.

Film quality: High-quality LDPE film should have good toughness and should not leave residue or tear when peeled off; otherwise, the mat itself will become a source of contamination.

3. Psychology and Functionality of Color Selection

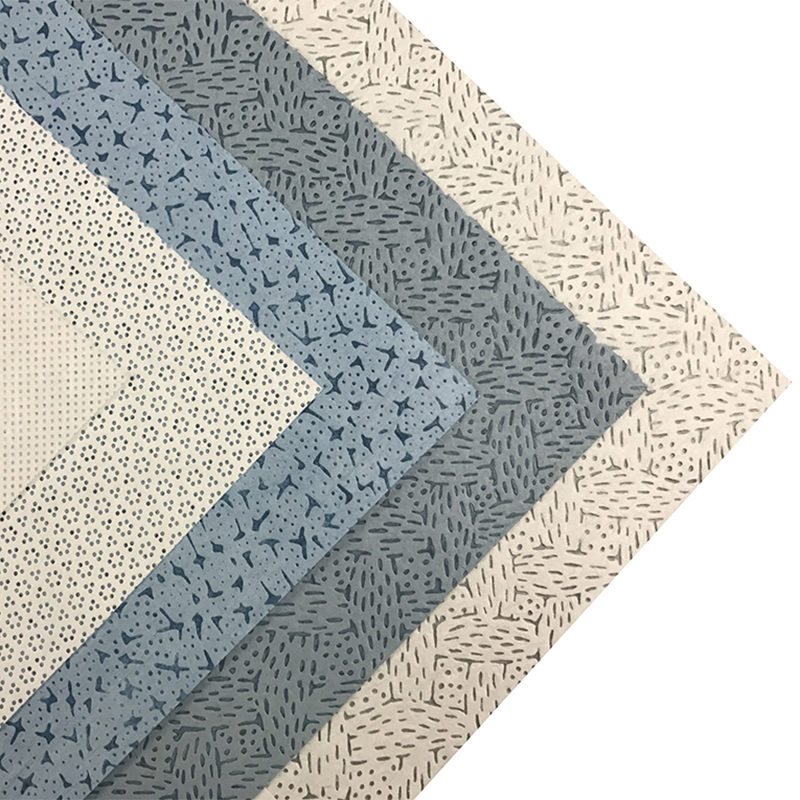

Sticky mats are usually available in blue, white, gray, or transparent.

Blue: The most commonly used color. It provides a strong contrast with dust, making it easier to visually determine when replacement is needed, and giving a psychological impression of professionalism and cleanliness.

White: Commonly used in laboratories to clearly observe specific colored contaminants.

Gray: More resistant to dirt, suitable for high-traffic semi-industrial areas.

4. Size and Installation Method

Size selection depends on your door width and traffic flow. Width: The width should cover the entire doorway to prevent people from walking around or stepping over the mat.

Length: The optimal length should ensure that both feet step on the mat at least 2-3 times.

Installation: Check if the back of the mat has a full adhesive layer to ensure it adheres firmly to the floor. If the floor material is special, it is recommended to use a dedicated dust-collecting mat frame for easy replacement and to prevent damage to the floor.

5. Anti-static and Antibacterial Requirements (Special Scenarios)

Hospital Environment: It is recommended to choose dust-collecting mats with added antibacterial agents to effectively inhibit the growth of microorganisms on the mat surface.

Electronics/Semiconductors: Products with ESD anti-static function must be selected to prevent electrostatic discharge from damaging sensitive components.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français