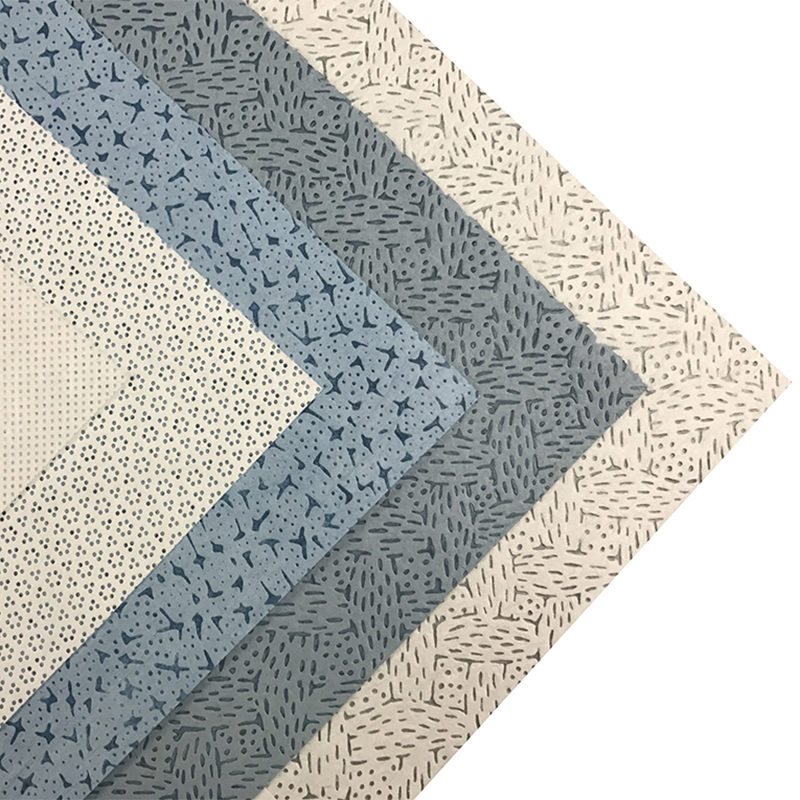

1. Material selection and process: ESD Wiper uses a combination of polyester or microfiber and high-performance permanent conductive fiber. Through special knitting or weaving processes, the fibers are more tightly bound and the possibility of fiber shedding is reduced. The arrangement and density of the fibers are precisely controlled to enhance the structural stability of the fabric.

2. Surface design: The wear-resistant surface design of ESD Wiper improves the durability of the product, reduces the friction and wear that may occur during wiping, and avoids the shedding of fibers and debris. This design ensures that the product can maintain its integrity and cleaning effect after repeated use and cleaning.

3. Clean room packaging: ESD Wiper uses clean room packaging technology in the production process to ensure that the product is in an environment with low particles, low ions and low non-volatile residues before leaving the factory, reducing the possible sources of pollution during use and improving the cleanliness and user experience of the product.

4. Chemical inertness: The material of ESD Wiper has good chemical compatibility. When it comes into contact with various chemicals and cleaning agents, it will not undergo chemical reactions or material degradation, thus avoiding fiber shedding and debris falling due to chemical reactions, ensuring its stability and reliability in various complex and harsh use environments.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français