How to Reduce Cross-Contamination in Cleanrooms? Proper Selection and Use of Nonwoven Wipes

Maintaining a contaminant-free environment is crucial in cleanroom operations, whether in electronics, pharmaceuticals, or biotech industries. Cross-contamination can compromise product quality, cause defects, and even lead to regulatory compliance issues. One of the simplest yet most effective ways to reduce contamination is through the proper use of nonwoven cleanroom wipes.

Understanding Cross-Contamination

Cross-contamination occurs when particles, microbes, or chemical residues are transferred from one surface to another. In a cleanroom, even microscopic debris can compromise sensitive processes. Sources include:

- Personnel movement and improper gowning

- Airborne particles or dust

- Contaminated tools or cleaning materials

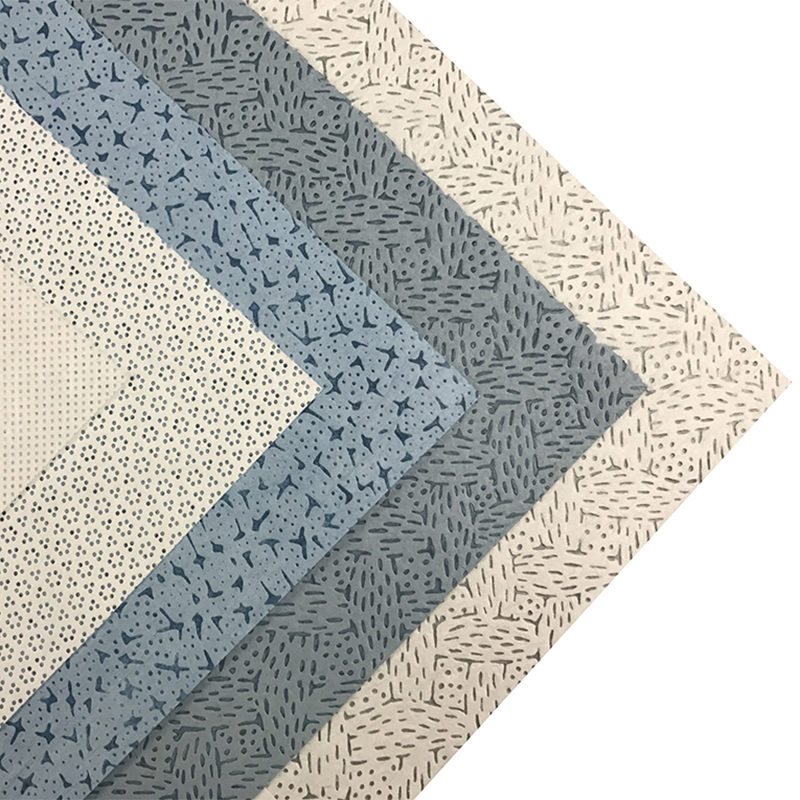

Choosing the Right Nonwoven Wipes

Selecting the correct wipe depends on the type of contamination you aim to control. Key considerations include:

- Material: Polyester or polyester/cellulose blends offer high absorbency and low particle generation.

- Lint-Free: Ensure the wipe produces minimal fibers to avoid particulate contamination.

- Pre-Saturated vs Dry: Pre-saturated wipes with IPA are ideal for equipment surfaces, while dry wipes are versatile for general cleaning.

- Size and Packaging: Choose convenient sheet sizes and sterile packaging to minimize handling contamination.

Proper Usage Techniques

Correct handling is just as important as material selection. Tips include:

- Always wear cleanroom gloves when handling wipes.

- Use a unidirectional wiping pattern to avoid spreading particles.

- Discard wipes after a single use on critical surfaces.

- Store in a dust-free, humidity-controlled environment.

Nonwoven Wipe Selection Table

| Wipe Type | Material | Recommended Use | Cleanroom Class |

| Standard Nonwoven Wipe | Polyester/Cellulose | General surface cleaning | ISO Class 7-8 |

| Lint-Free Polyester Wipe | 100% Polyester | Critical surface wiping | ISO Class 5-6 |

| Pre-Saturated IPA Wipe | Polyester/IPA | Electronics and equipment cleaning | ISO Class 5-6 |

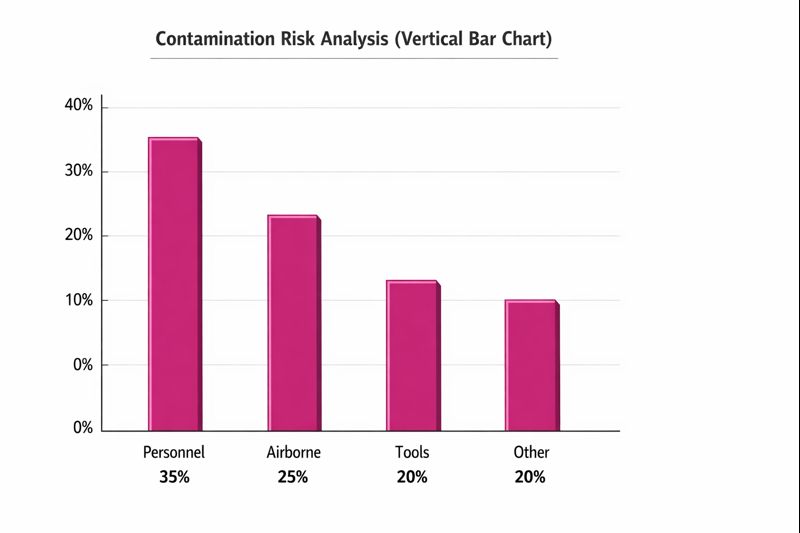

Contamination Risk Analysis (Vertical Bar Chart)

The vertical bar chart demonstrates that personnel movement contributes the most to cross-contamination in cleanrooms, emphasizing proper gowning and wipe handling.

Conclusion

By carefully selecting high-quality nonwoven wipes and using them with correct techniques, cleanroom operators can significantly reduce cross-contamination risks. Consistency in cleaning protocols and staff training are essential for maintaining ISO Class 5-8 environments.

For reliable cleanroom wipes that meet international standards, check our Nonwoven Cleanroom Wipes collection, tested for low particle release and optimal absorbency. Invest in quality materials today to ensure a safer, contamination-free workspace.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français