Cleanroom wipers are typically used in two ways: dry wiping and wet wiping, depending on their material characteristics and application scenarios:

(1) Dry Wiping

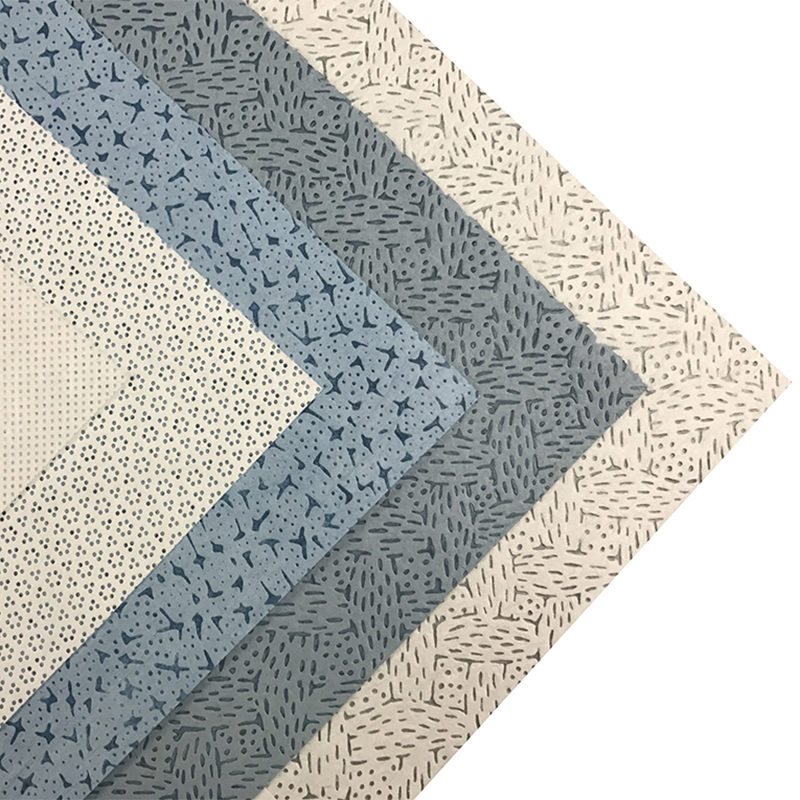

Material Characteristics: Dry-wiping cleanroom wipers are usually made of high-density polyester or polyamide fibers. They are characterized by high water absorption, low fiber shedding, and low particle release.

Applicable Scenarios: Primarily used to remove dust and particles from surfaces, suitable for processes that do not require corrosive cleaning. Their low particle release makes them the preferred consumable for industries such as semiconductors, photovoltaics, and LEDs.

Advantages: Dry-wiping wipers do not require additional cleaning agents during use, effectively avoiding secondary contamination and maintaining a high level of cleanliness in the environment.

(2) Wet Wiping

Material Characteristics: Wet-wiping wipers are usually treated with a specific anti-static treatment on the surface, or undergo ion cleaning and residue cleaning processes after dry wiping to reduce surface charge.

Applicable Scenarios: Primarily used for cleaning electronic components or optical lenses that are extremely sensitive to static electricity. Due to their anti-static properties, they can effectively prevent particle contamination caused by electrostatic attraction.

Advantages: When performing wet wiping, cleanroom wipers are usually used with deionized or low-ion cleaning agents to ensure neutralization during the cleaning process.

Why do Cleanroom Wipers need to undergo "ion cleaning" or "residue cleaning"?

Ion cleaning and residue cleaning are key processes to ensure the quality of Cleanroom Wipers, mainly for the following reasons:

(1) Removal of Residues and Additives

Removal of Impurities: During the manufacturing process, the surface of the wiper may have residual oil, additives, or other small impurities from the production equipment. The ion cleaning process can effectively remove these residues, preventing them from being transferred to the cleaned surface during actual use.

Improved Cleanliness: Through ion cleaning, the residues on the surface of the wiper are thoroughly removed, allowing it to meet the ISO 14644 cleanroom standard and ensuring that it does not become a source of secondary contamination.

(2) Reducing Charge and Electrostatic Adsorption

Charge Neutralization: The ion cleaning process neutralizes the charge on the surface of the wiping cloth. Untreated wiping cloths may carry positive or negative charges, easily attracting tiny particles from the air or causing electrostatic adsorption on the cleaned object.

Preventing Electrostatic Contamination: For processes extremely sensitive to static electricity, such as integrated circuit (IC) manufacturing, ion-cleaned wiping cloths significantly reduce the risk of electrostatic discharge (ESD), protecting delicate components from damage.

(3) Enhancing Antibacterial and Antifungal Properties

Cleanliness and Hygiene: The ion cleaning process is usually accompanied by high-temperature drying and ultraviolet sterilization. This not only removes residues but also kills bacteria, fungi, and spores on the surface of the wiping cloth, preventing their growth during use.

Ensuring Safety: For fields such as medical, pharmaceutical, and biotechnology, wiping cloths must meet strict hygiene standards, and ion cleaning is a necessary step to achieve this goal.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français