Main Differences Between Semiconductor, Pharmaceutical, and Laboratory Industries

1. Different Cleanliness Level Requirements: Semiconductor production lines often use ISO Class 5-6 (or higher) cleanrooms, with extremely strict requirements for particulate concentration; pharmaceutical GMP workshops typically require Class 100-Class 1000; laboratories mostly require Class 100-Class 10000, adjusted flexibly according to the nature of the experiments.

2. Material Compatibility and Sterilization Methods: Semiconductor processes often use organic solvents (such as IPA) and acid/alkali cleaning agents, requiring chemically resistant and low-dust-generating wipes; the pharmaceutical industry emphasizes sterility and high-temperature sterilization, often using sterilized cleanroom wipes; laboratories, considering the diversity of chemical reagents and biological samples, have even higher requirements for the chemical inertness of the wipes.

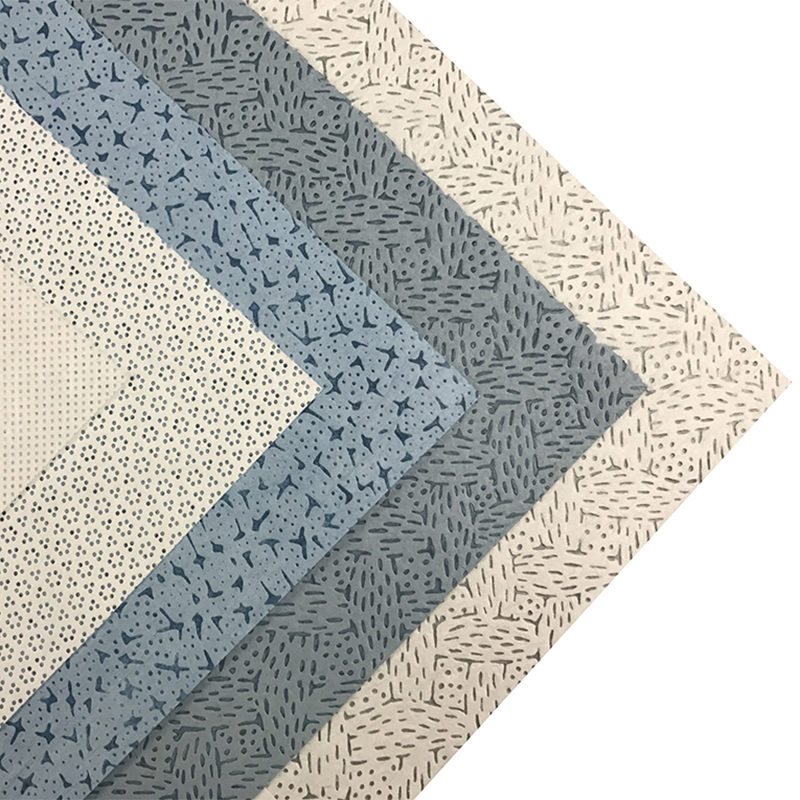

3. Impact of Process Flow on Cleanroom Wiper Fabric

Semiconductor wafer processing is extremely sensitive to surface scratches, requiring soft fabrics with low fiber shedding; pharmaceutical packaging and container cleaning prioritizes no residue after liquid absorption; routine laboratory cleaning focuses on rapid absorption and reusable durability.

4. Regulatory and Quality Standards

Pharmaceutical manufacturing must comply with GMP, ISO 13485, and other pharmaceutical regulatory standards; semiconductor manufacturing requires JEDEC and NEBB certification; laboratories mostly follow ISO 14644-1 and internal laboratory safety specifications.

Does the Cleanroom Wiper support the use of alcohol, IPA solvents, or chemical cleaning agents?

1. Material Inherent Chemical Resistance

Most Cleanroom Wipers use 100% polyester or microfiber structures, allowing for direct application of solvents such as alcohol and IPA for cleaning without fiber shedding.

2. Manufacturer's Explicit Recommendation

The manufacturer states in the product instructions that alcohol, IPA solution, or other chemical cleaning agents can be added to the cleaning cloth for use, and its performance is maintained after sterilization.

3. Safety Precautions During Use

Although the material is solvent-resistant, high concentrations of strong acids and alkalis should still be avoided to prevent microscopic damage to the fiber structure. After use, ensure the cloth is fully absorbed and replace it promptly to prevent residual liquid from causing secondary contamination.

4. Enhanced Cleaning Efficiency

Appropriate amounts of alcohol or IPA can significantly improve the efficiency of removing oil stains and particles, especially in semiconductor and pharmaceutical processes, achieving rapid decontamination while maintaining low dust generation.

How do the absorbency and low dust generation properties of the Cleanroom Wiper affect actual usage results?

Impact of Absorbency and Low Dust Generation Properties on Actual Usage Results

1. High Absorbency Improves Cleaning Efficiency

The wiping cloth, with its microfiber or double-needle-punched polyester structure, absorbs liquid quickly and has a large capacity, removing large amounts of liquid in one pass and reducing secondary contamination caused by multiple wipings.

2. Low Dust Emission Prevents Secondary Contamination

The low particle release characteristic ensures that no floating fibers or dust are generated during wiping, making it particularly suitable for semiconductor wafer surfaces and pharmaceutical container interiors where particles are highly sensitive.

3. Direct Contribution to Product Yield and Quality

In high-cleanliness environments, the synergistic effect of liquid absorbency and low dust emission significantly reduces defect rates and improves finished product yield; in laboratory use, it maintains the cleanliness of samples and instruments, avoiding cross-contamination.

4. Equipment Compatibility

When used in automated cleaning equipment, the low-dust wiping cloth will not clog the filtration system or leave residue, ensuring long-term stable operation of the equipment; high liquid absorbency reduces cleaning fluid consumption and lowers operating costs.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français