Main uses of face masks:

1. Medical protection: In hospitals, clinics, and other medical settings, face masks are used to block droplets, bacteria, and viruses, preventing cross-infection.

2. Industrial protection: In production environments with high concentrations of dust, chemical gases, or oily particles, face masks (such as the KN/KP series) provide specialized particle filtration to protect workers' respiratory systems.

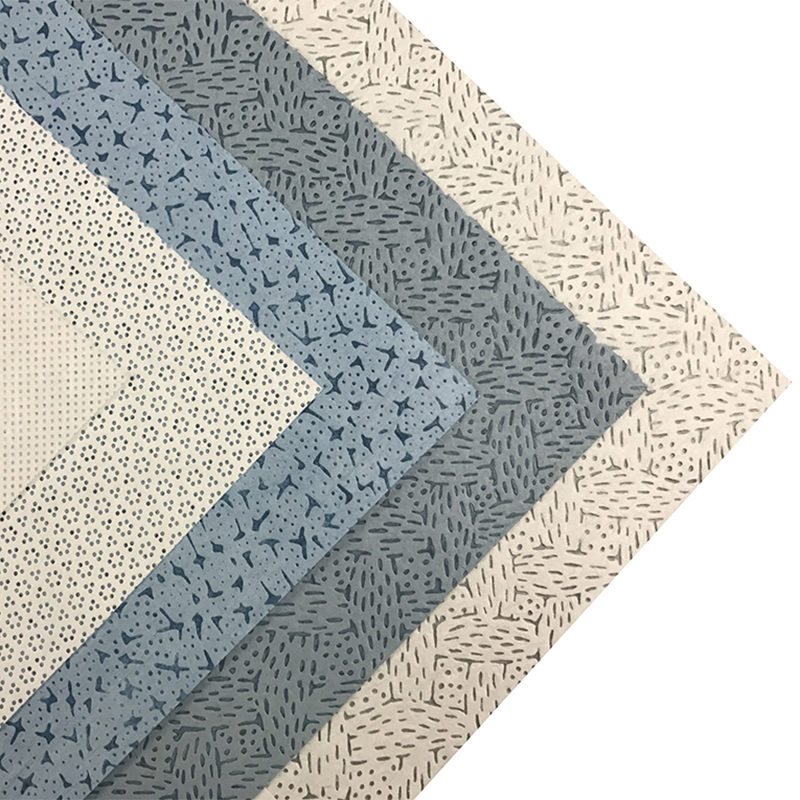

Is the face mask made of non-woven fabric?

1. Main material is non-woven fabric: The outer and inner layers of disposable face masks typically use polypropylene (PP) non-woven fabric, which is lightweight, breathable, and disposable.

2. Advantages of non-woven fabric: Randomly distributed fibers and high porosity provide basic filtration while maintaining comfort.

3. Wholesale production: Suzhou Jujie Electron Co., Ltd.'s face masks use non-woven fabric as the base material and are supplied to wholesale channels to meet large-volume purchasing needs.

What type of filter membrane is used?

1. Meltblown Nonwoven Fabric: As the core filter layer of a mask, meltblown fabric is made of polypropylene polymer meltblown into fibers by high-speed airflow. The fiber diameter is 1-5µm, forming a three-dimensional mesh structure that provides high-efficiency particle filtration.

2. Filtration Efficiency Grades: According to standards such as GB2626-2006, meltblown membranes are classified into grades such as KN100/KP100, KN95/KP95, KN90/KP90, and KN80/KP80, corresponding to particle filtration efficiencies of ≥99.97%, ≥95%, ≥90%, and ≥80%, respectively.

3. Composite Filter Material: In some high-protection masks (such as N95), the meltblown layer is composited with needle-punched cotton or other intermediate layers to form a multi-layer structure, further improving barrier performance and maintaining low breathing resistance.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français