Best Operating Procedure for LCDs, OLEDs, and Optical Lenses

1. Preparation: Wear anti-static gloves and ensure your hands are dust-free.

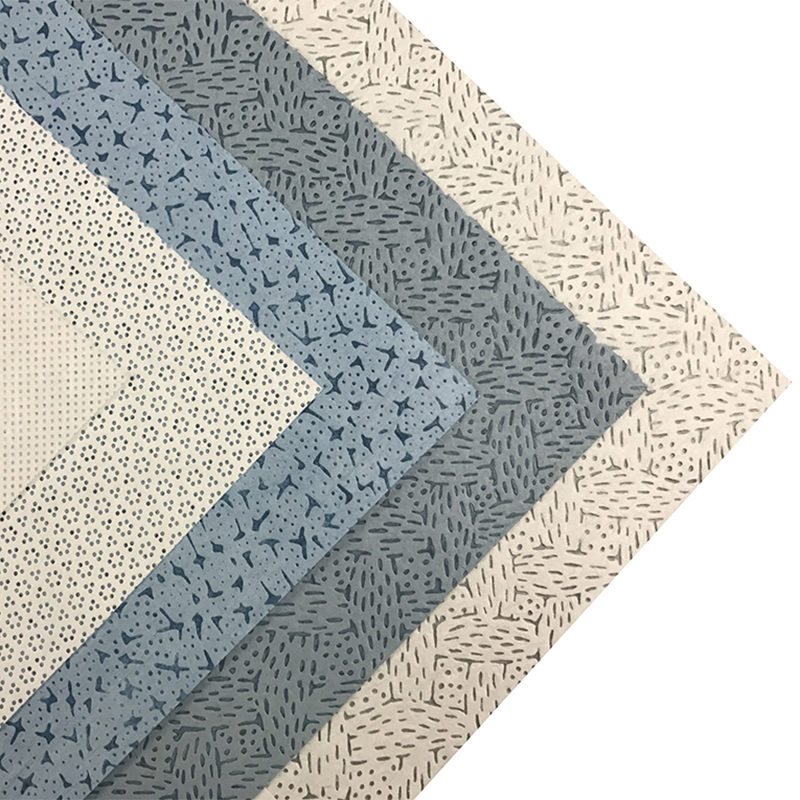

Use disposable Cleanroom Wipers that have been cleaned in a cleanroom to avoid cross-contamination.

2. Alternate Dry and Wet Wiping: First, gently remove surface dust with a clean, dry cloth; then wipe a second time using a pre-wetted (IPA + deionized water) or a dual-purpose microfiber cloth.

When wet wiping, use a gentle "Z" or circular motion to avoid scratching by rubbing back and forth in the same direction.

3. Change Cloth: Replace the cloth after wiping an area of 5cm² to prevent the re-spread of contaminated particles.

For high-value optical components, it is recommended to use a separate pre-wetted cloth for each wipe.

4. Inspection and Confirmation

After completion, check for residual particles or water stains under cleanroom lighting; if necessary, use low-pressure airflow for secondary dust removal.

Record the batch number of the cloth used and the operation time for quality traceability.

How to identify genuine Cleanroom Wipers and avoid buying low-quality counterfeits?

Key points for identifying genuine Cleanroom Wipers

1. Packaging and Protection

Genuine products use double-layer dust-free packaging (inner heat-sealed, outer aluminum foil), and the packaging is printed with an anti-counterfeiting QR code or anti-counterfeiting code.

The packaging clearly indicates the manufacturer, Suzhou Jujie Electron Co., Ltd., the product model, and ISO and NEBB certification information.

2. Material and Process Identification

Check the cloth label to confirm it is 100% polyester microfiber or carbon fiber/silver fiber blend, and indicate laser-cut or heat-sealed edges.

Genuine products have smooth, burr-free edges, and do not show fiber shedding under light. 3. Quality Inspection Reports: A qualified Cleanroom Wiper must be accompanied by a particle count report, an electrostatic discharge (ESD) test report, and a liquid absorption rate report. These reports are usually included in the packaging as PDFs or provided with download links.

4. Supply Chain Traceability: Purchasing through official channels (company website, authorized distributors, or Alibaba official store) allows you to view the production batch and manufacturing date on the order page, preventing low-quality counterfeit products from entering the market.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français