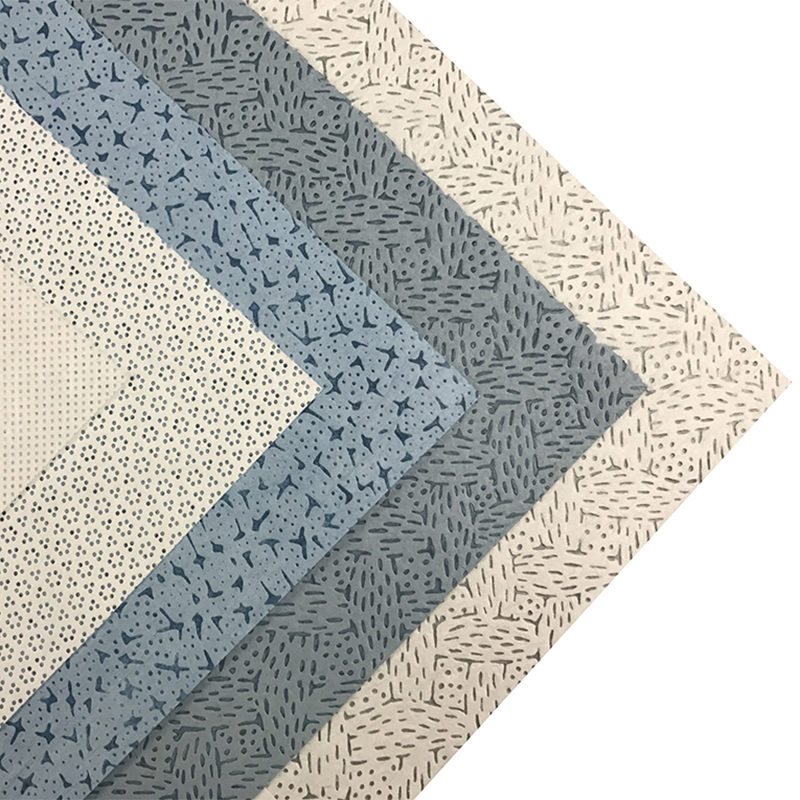

The best materials for Cleanroom Wiper for electronic screens and optical components:

1. Microfiber Polyester: Made of 100% polyester microfibers with a fiber diameter of less than 0.5µm, it boasts extremely high absorbency and a very low fiber shedding rate, enabling thorough cleaning of LCD, OLED, and optical lens surfaces without leaving any particles.

2. Carbon Fiber/Silver Fiber Blend (ESD Microfiber): Incorporating conductive carbon or silver fibers into the microfiber base significantly reduces static electricity buildup during wiping, preventing dust adsorption or surface scratches caused by static electricity. It is particularly suitable for optical components that are extremely sensitive to static electricity.

3. Nonwoven Fiber (Cellulose + Polyester): A spunlace nonwoven fabric of 55% cellulose + 45% polyester combines high absorbency with chemical compatibility, suitable for display panels requiring wet wiping with alcohol or deionized water, and leaves minimal residue.

4. Heat-sealed/Laser-cut Edges: Edges processed with laser cutting or heat sealing prevent fiber shedding, ensuring dust-free wiping in high-cleanliness (ISO 5-6) environments.

What are the advantages of Cleanroom Wiper in terms of anti-static and waterproof performance compared to ordinary wipes?

Anti-static and Waterproof Advantages Compared to Ordinary Wipes

1. Low Static Electricity Generation: By incorporating conductive carbon/silver fibers into the fibers, the charge generated during wiping is significantly lower than that of ordinary polyester cloth, preventing static electricity from attracting dust and improving cleaning efficiency.

2. High Water/Liquid Absorption Capacity: The microfiber structure has a large specific surface area, with a water absorption rate 4-5 times that of ordinary cotton cloth. It can quickly absorb liquids and keep the surface dry, preventing water stains.

3. Waterproof Coating or Hydrophobic Treatment: Some Cleanroom Wipers have a hydrophobic coating on the surface, causing water droplets to roll off upon contact with liquids, further reducing the risk of liquid penetration.

4. Low Particle Release: Laser cutting and heat-sealing technology ensures no fiber debris is generated at the edges, meeting NEBB and ISO 5-6 particulate emission standards, far superior to the fiber shedding problems of ordinary wiping cloths.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français