If you need any help, please feel free to contact us

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat is the difference between antistatic shoes and regular shoes?

The core differences between antistatic shoes and regular shoes lie in three key dimensions: function, material design, and application scenarios. Suzhou Jujie Electron Co., Ltd.'s products focus on the specialized needs of "cleanroom safety" and "static protection":

1. Function: Static Protection vs. Everyday Wear

Regular shoes are designed to meet daily walking, warmth, or decorative needs and lack static protection. Antistatic shoes, on the other hand, utilize special materials such as conductive fibers and antistatic rubber, and structures such as conductive soles and linings, to quickly conduct static electricity from the human body to the ground, preventing the risk of static electricity accumulation leading to damage to electronic components, fire, or explosion. They are essential protective equipment for static-sensitive environments such as cleanrooms, electronics factories, and pharmaceutical workshops.

2. Material Design: Balancing Conductivity and Cleanliness

Ordinary shoes are often made of ordinary rubber, leather, or synthetic materials, which lack conductivity and are prone to static electricity generation. For example, plastic soles can easily become charged after friction.

Anti-static shoes: Suzhou Jujie Electron Co., Ltd's products utilize specialized anti-static materials, such as conductive rubber soles and anti-static PU/PU+mesh uppers. Some styles also feature an internal conductive thread to ensure rapid static dissipation. Furthermore, these shoes meet ISO Class 5/6 cleanroom standards, and are lint-free and dust-free, minimizing contamination.

3. Application Scenarios: Professional Environments vs. General Use

Ordinary shoes are suitable for everyday office work and outdoor activities. However, anti-static shoes are mandatory in static-sensitive industries such as cleanrooms, semiconductor factories, and pharmaceutical production workshops. For example, in Suzhou Jujie Electron Co., Ltd's ISO Class 5 cleanroom, employees must wear anti-static shoes before entering, as static electricity could damage delicate electronic components.

How to Properly Wear Anti-static Shoes?

Properly wearing anti-static shoes is crucial to ensuring they deliver the best possible protection. Suzhou Jujie Electron Co., Ltd's product design prioritizes both convenience and safety. Key points include:

1. Matching Wear: Combining with Anti-Static Socks/Insoles

Anti-static shoes must be worn with anti-static socks or conductive insoles to create a complete conductive circuit from body to shoe to ground. Wearing only ordinary socks prevents static electricity from being effectively conducted into the shoes, significantly reducing their effectiveness.

2. Regular Testing: Ensure Performance Meets Standards

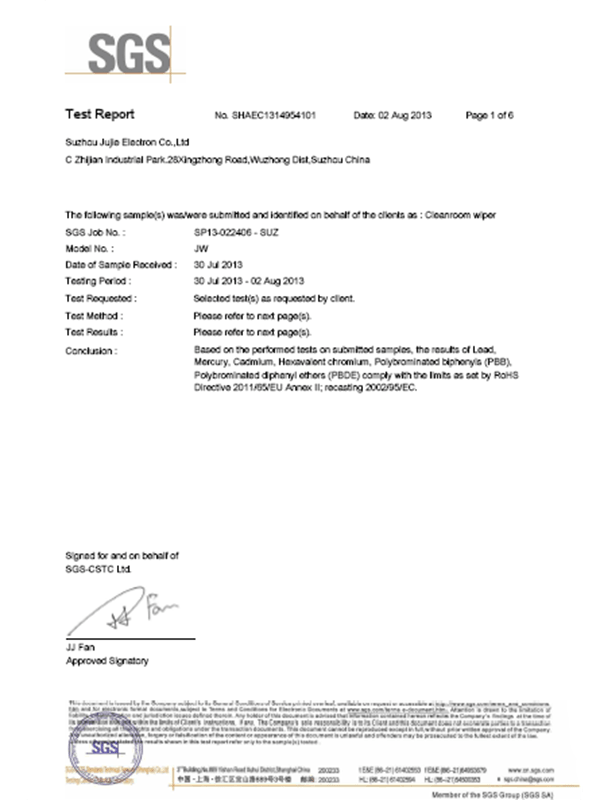

The conductive properties of anti-static shoes degrade over time, so they must be tested every 6-12 months. Suzhou Jujie Electron Co., Ltd is equipped with high-end testing equipment imported from Germany and the United States, including infrared spectrometers and liquid particle counters, and offers professional performance testing services to ensure our products consistently comply with national standards such as GB 4385-1995.

3. Daily Maintenance: Extending the Lifespan

Cleaning: Wipe the shoe surface with a soft cloth dampened with neutral detergent. Avoid using strong acids or alkalines to prevent corrosion.

Storage: Store in a dry, well-ventilated area, away from direct sunlight.

Replacement: If the sole shows significant wear, replace it promptly to ensure effective protection.

4. Environmental Compatibility: Comply with Cleanroom Standards

In Suzhou Jujie Electron Co., Ltd's ISO Class 5/6 cleanrooms, employees are required to wear lint-free, dust-free anti-static shoes (such as the JS-010 white anti-static slippers) to prevent contamination from falling fibers or dust. Furthermore, the soles must meet "low dust generation and low static electricity" requirements to ensure cleanroom air quality meets standards.

What styles of anti-static shoes does Suzhou Jujie Electron Co., Ltd offer?

Suzhou Jujie Electron Co., Ltd, a professional manufacturer of anti-static shoes, leverages a 33,000-square-meter modern production base (including an 8,000-square-meter lint-free workshop) and 48 fully automated production lines (including imported laser and ultrasonic cutting machines from Japan). Its products cover a wide range of scenarios. The following are key styles and their advantages:

1. Anti-static Slippers: A Balance of Comfort and Protection

JS-009 Anti-static Slippers: Featuring a black anti-static rubber sole and a breathable PU upper, they are suitable for daily use in cleanrooms, offering both comfort and protection.

JS-010 White Anti-static Slippers: Designed for ISO Class 5/6 cleanrooms, they feature a lint-free white PU upper and a conductive rubber sole, resulting in low dust and static electricity, meeting NEBB certification standards.

JS-011 Anti-static Slippers: Featuring a blue upper and black sole, and the "Antistatic Shoes" logo printed on the upper, they meet both protection needs and enhance visual recognition.

2. Anti-static Four-Hole Shoes: A Combination of Stability and Professionalism

These four-hole shoes feature a "four-hole strap" design, with an anti-static mesh or PU upper and a conductive rubber sole. They are suitable for environments requiring prolonged standing or walking (such as electronics production lines and pharmaceutical workshops). The adjustable straps ensure a secure fit, while the breathable mesh material enhances comfort.

3. Anti-static Mesh Shoes: The Optimal Choice for Breathability and Flexibility

These mesh shoes utilize a "mesh + rubber" combination, with a breathable mesh upper and a conductive rubber sole. They are suitable for cleanroom use in summer or high-temperature environments. Their lightweight and flexible design ensures comfort during long work hours, while the mesh's low dust generation meets cleanroom environmental requirements.

4. Customized Services: Meeting Special Needs

Suzhou Jujie Electron Co., Ltd can provide customized anti-static shoes based on customer needs, including size adjustments, color modifications, and special features. Our fully automated production line enables rapid response to customization requests, ensuring consistent product quality.