If you need any help, please feel free to contact us

Clean room products are a range of equipment and materials designed for dust-free environments to control contamination and maintain specific cleanliness levels.

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat is the core function of cleanroom products?

Cleanroom products are key tools for maintaining the "cleanliness" of a dust-free environment. Their core functions revolve around "contamination control" and "environmental stability," which can be broken down into the following dimensions:

1. Physically isolating pollutants and blocking the transmission path of contamination

Cleanroom wipes utilize a microfiber and dust-free design. Fibers are only a few microns in diameter, effectively absorbing micron-sized particles. Laser-cut edges completely eliminate secondary contamination caused by fiber shedding during wiping. Latex finger cots provide a "full-cover" protection, preventing hand contaminants such as sweat, dandruff, and oil from contacting sensitive components, thus eliminating contamination at the source.

2. Ensure process stability and improve production yield.

In high-precision industries such as semiconductors and biomedicine, the low contamination properties of cleanroom products are directly linked to production yield:

Cleanroom wipes leave no fibers or chemicals when wiping equipment surfaces, preventing them from affecting chip lithography accuracy.

The low ion release properties of latex finger cots prevent static damage to electronic components (e.g., electrostatic discharge leading to chip breakdown).

Cleanroom printer paper, notebooks, and other stationery use a "dust-free pulp" that eliminates paper dust or toner particles when writing, ensuring the accuracy of laboratory records.

3. Comply with industry standards and mitigate regulatory risks.

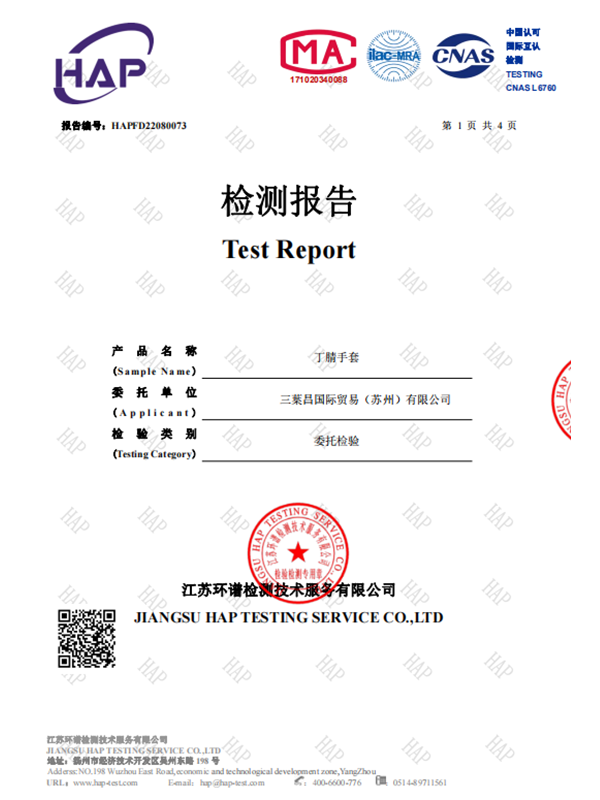

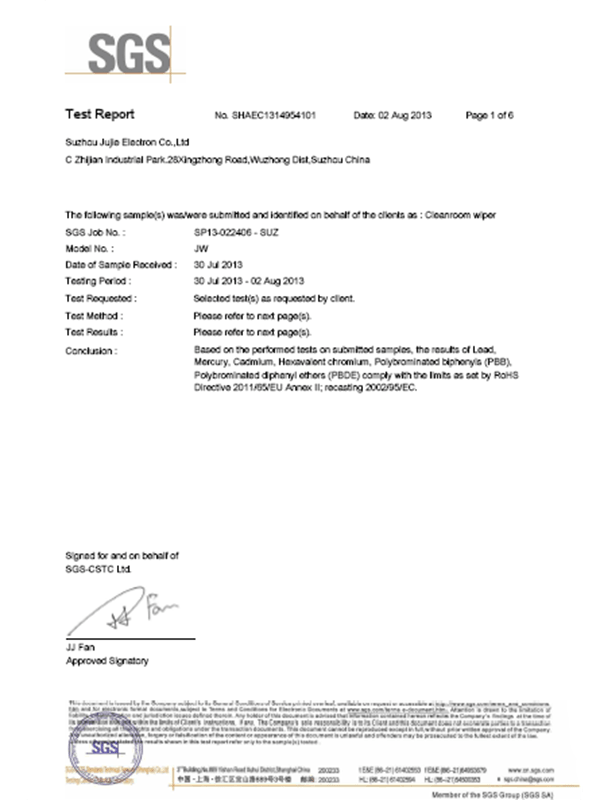

Suzhou Jujie's products strictly adhere to ISO Class 5/6 cleanroom standards and are NEBB-certified, ensuring compliance with regulatory requirements in mandatory certification applications such as pharmaceuticals (e.g., GMP workshops), electronics (e.g., semiconductor cleanrooms), and biology (e.g., PCR labs).

What are the differences in material and function between cleanroom wipes and "clean wipes"?

Cleanroom wipes only provide visual cleanliness, while cleanroom wipes are professional-grade dust-free protective tools. The difference between the two lies in their specialized materials and targeted functions. A detailed comparison is as follows:

1. Material: From "Ordinary Fiber" to "Ultrafine Dust-Free Fiber"

Cleanroom wipes: Made from a microfiber composite material with a fiber diameter ≤ 0.1μm, they undergo a lint-free treatment to prevent fiber shedding. They also feature an anti-static treatment to prevent static electricity from attracting airborne particles.

Ordinary cleanroom wipes: Mostly made from cotton or ordinary synthetic fibers, they have larger fiber diameters, are prone to linting and static electricity, and cannot meet the requirements of a dust-free environment.

2. Function: From "wiping visible stains" to "controlling microparticle contamination"

Cleanroom wipes: They offer the triple function of "absorption, retention, and release." The capillary action of the microfibers absorbs micron-sized particles, while the lint-free edges prevent fiber residue, ensuring a clean surface after wiping. Their chemical resistance makes them suitable for semiconductor cleaning applications. Ordinary rags: They can only remove visible stains and cannot control microparticle contamination. Furthermore, the rough edges of ordinary rags will shed during wiping, directly contaminating the cleanroom environment.

3. Application Scenario: From "Daily Cleaning" to "High-Precision Cleanrooms"

Cleanroom rags: Designed specifically for high-precision cleanrooms such as those used in semiconductor, pharmaceutical, and biological applications, and must pass particle emission testing.

Ordinary rags: They are only suitable for ordinary environments such as homes and offices and cannot be used in cleanrooms.

For example, Suzhou Jujie's cleanroom rags utilize a "laser cutting + ultrasonic edge sealing" process, resulting in smooth, burr-free edges. Ordinary rags, on the other hand, have rough "scissor-cut" edges that shed during wiping, directly contaminating the cleanroom environment.

How does Suzhou Jujie's cleanroom product production line ensure consistent product quality?

Suzhou Jujie achieves consistent product quality through "full-process intelligent production" and high-end equipment. Its core advantages can be categorized into the following dimensions:

1. Large-Scale Intelligent Production Lines: From Manual Operation to Fully Automated Process

In 2018, Suzhou Jujie invested in Jujie Ultra-Clean Technology Shuyang Co., Ltd., establishing 48 automated weaving, washing, and shaping production lines covering the entire process from raw materials - weaving - washing - shaping - testing - and packaging:

Automatic Weaving Line: Utilizing shuttleless looms, the fiber density can be precisely controlled, ensuring consistent adsorption capacity across the entire cleaning cloth.

Automatic Washing Line: Utilizing multi-stage filtration and ultrasonic cleaning, impurities are removed from the fibers, ensuring that each batch of cleaning cloths meets cleanliness standards.

Automatic Shaping Line: Utilizing hot air shaping and vacuum suction, the smoothness of the cleaning cloths is consistently maintained, preventing contamination caused by wrinkles. Furthermore, the Shuyang factory's "lint-free workshop" is built to ISO Class 5 cleanroom standards, ensuring a dust-free production process and eliminating contamination at the source.

2. Precision Control of Imported Equipment: From "Experience-Based Judgment" to "Data-Driven Testing"

The production line is equipped with high-end equipment imported from Japan, Germany, and the United States, achieving triple testing for "material, cleanliness, and functionality":

Japanese laser cutting machines: Precision cut the edges of the wipes with an error of ≤0.1mm, completely eliminating fiber residue;

German infrared spectrometers: Detect material composition consistency, ensuring consistent adsorption capacity for each batch of wipes;

US liquid particle counters: Monitor particle counts during the washing process, ensuring that the cleanliness of the wipes meets ISO Class 5 standards;

South Korean static testers: Measure the static decay time of latex finger cots to ensure their anti-static performance meets standards.

Each batch of products undergoes a comprehensive inspection, with a defect rate of less than 0.1%, ensuring that each product consistently meets standards for particle release and static decay time.

3. Double Improvement in Production Capacity and Quality: From "Small Batch Customization" to "Scaled Supply"

The expansion of the production line has increased production capacity tenfold, meeting the market's large-scale demand for cleanroom products while ensuring consistent product quality.

In addition, Suzhou Jujie has achieved NEBB-certified cleanroom standards, ensuring its products meet international industry requirements and helping customers achieve their goals of "efficient production and quality control."

As a leading company in the Other Cleanroom Products field, Suzhou Jujie Electron Co., Ltd. leverages its technological strength and quality control system to continuously provide global customers with "zero-pollution, highly stable" cleanroom solutions, contributing to the upgrading of industries in dust-free environments.