If you need any help, please feel free to contact us

A sticky mat is a ground-laying material used to clean soles and wheels, usually used in factories, laboratories, hospitals, and other places that need to be kept highly clean. They are made of multiple layers of viscous material that effectively trap and hold dust, dirt, and microorganisms carried by the sole. The use of sticky MATS helps to reduce indoor pollution, keep the environment clean, and improve hygiene standards in the work area.

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

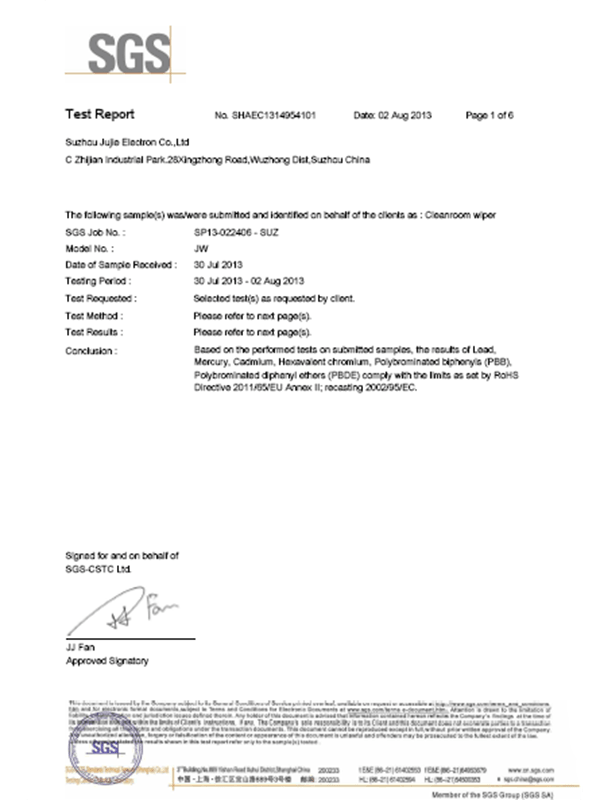

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat pollutants do sticky mats absorb?

As a key protective tool for clean environments, sticky mats, with their multi-layered sticky structure, effectively capture a wide range of pollutants, including:

Particulate matter: Dust, sand, and fibers are the most common pollutants carried by shoe soles and wheels;

Microorganisms: Bacteria and fungal spores are among the most common pollutants found on shoe soles and wheels. Microbial contamination prevention and control is crucial in healthcare and laboratory settings;

Oil and chemical residues: In some industrial settings, shoe soles may be contaminated with oil or chemicals, and sticky mats can absorb these pollutants;

Other impurities: Metal debris and paint particles prevent them from entering cleanrooms and causing equipment damage or environmental disturbances.

Sticky mats manufactured by Suzhou Jujie Electron Co., Ltd. utilize a multi-layer composite sticky material design to specifically capture pollutants of varying particle sizes. Their long-lasting, non-detachable adhesion ensures that pollutants are firmly trapped, preventing secondary contamination.

Why do sticky mats clean shoe soles and wheels?

The core principle of sticky mats for cleaning shoe soles and wheels stems from their dual mechanisms of "physical adsorption + structural design":

The function of the sticky material: The sticky mat's surface is coated with a highly sticky adhesive layer. When contacted by a shoe sole or wheel, the adhesive layer absorbs pollutants through intermolecular forces.

Multi-layered structure: The multiple sticky layers capture pollutants layer by layer, preventing failure after a single layer becomes saturated, thus extending the service life.

Pressure adaptability: When a shoe sole is stepped on or a wheel rolls, the pressure ensures that the sticky material comes into full contact with pollutants, improving adsorption efficiency.

Scenario adaptability: Suzhou Jujie can customize the sticky mat's adhesive strength, thickness, and number of layers for different scenarios (such as factories and laboratories) to ensure the cleaning effect is matched to the specific scenario.

Suzhou Jujie Electronics Co., Ltd., with its ISO 5/6 cleanroom and 48 fully automated production lines, precisely controls the formula and structure of the sticky material, ensuring that the sticky mat is both efficient and durable when cleaning shoe soles and wheels, meeting the stringent requirements of high-cleanliness environments.

What are the advantages of sticky mats produced by Suzhou Jujie Electronics Co., Ltd.?

Suzhou Jujie Electronic Co., Ltd., a professional sticky mat manufacturer, derives its product advantages from a comprehensive approach to technology, production capacity, and quality:

Technological Leadership: Leveraging its high-tech enterprise status, Jujie Electronics has mastered the core formula and multi-layer structure of its sticky mats, ensuring long-lasting adhesion and minimal residue.

Production Capacity and Scale: Following an investment expansion in 2018, the factory has expanded to 33,000 square meters, adding 48 fully automated production lines, increasing production capacity tenfold and enabling rapid response to large-scale orders.

Quality Assurance: Our cleanroom is built to ISO Class 5/6 standards and equipped with high-end testing equipment imported from Germany and the United States, ensuring that every batch of sticky mats meets cleanroom standards.

Customization: We offer a variety of sticky mat specifications for diverse cleaning environments, such as factories, hospitals, and laboratories, to meet individual cleaning needs.